Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

$ 7.99 · 4.5 (325) · In stock

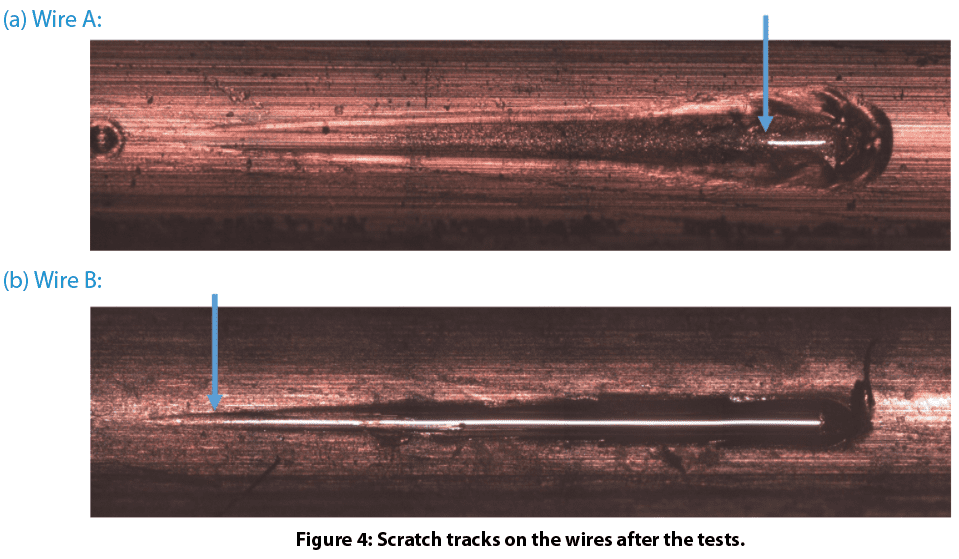

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

An Introduction to Wire Arc Additive Manufacturing [2020 Update] - AMFG

COF Evolution of copper wires during the wear tests.

How To Evaluate Mechanical Materials

The Material of Wire Wheel Cup Brush: Made of carbon steel material. Designed with reasonable crimped wire curvature and increased bristle thickness

6 Pcs Wire Wheel Cup Brush Set,1/4In Round Shank Wire Brush for Drill Attachment, for Cleaning Rust, Stripping and Abrasive

SEM image of worn surface after abrasive wear test of (a) neat epoxy

BUILDPRO MAX Slotted 4' x 3' Welding Table w/FREE Fixturing Kit

Beryllium Copper: What Is It? How Is It Used? Types Of

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

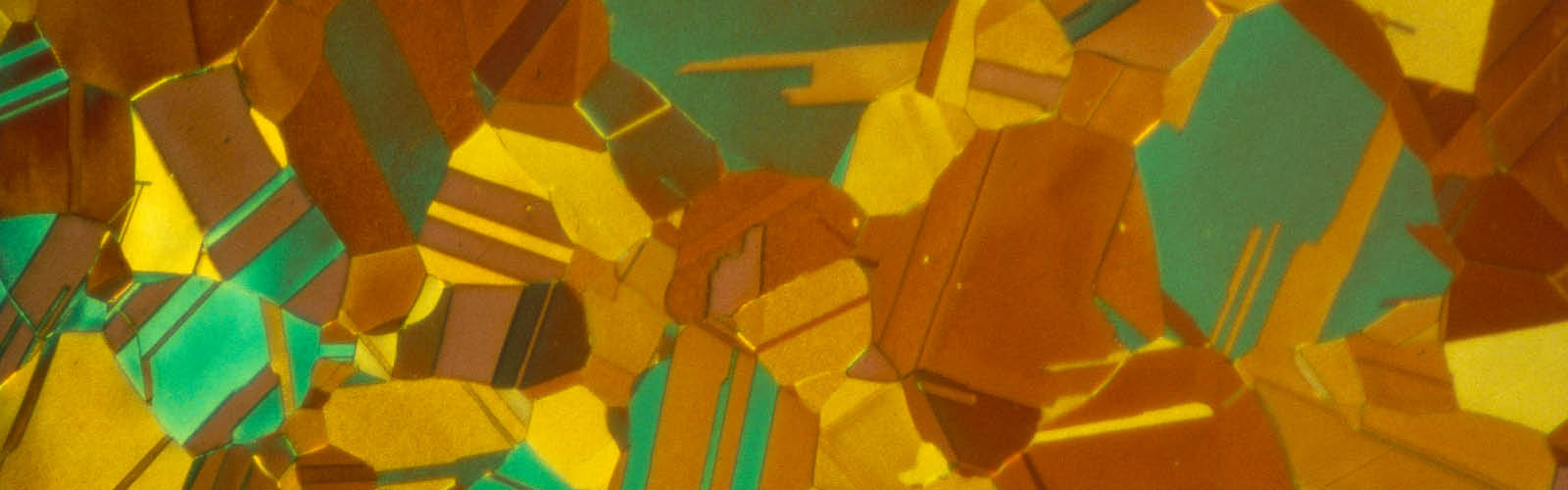

Metallography of copper and copper alloys insight